There are more than 4 million Class 8 (tractor-trailer size) vehicles on the road in America today, with more than 98 percent powered by diesel technology.

According to Allen Schaeffer, Executive Director of the Diesel Technology Forum;

“Technology for commercial trucking is changing rapidly and that includes all vehicle, fuel and powertrain choices for the future. Aspirations and predictions for new fuels and technologies are high but must be evaluated in the context of reality.

Diesel will remain the predominant fuel for commercial vehicles through at least 2025, when it retains 96 percent of the medium and heavy-duty market.

Diesel is the most energy efficient internal combustion engine. It has achieved dominance as the technology of choice in the trucking industry over many decades and challenges from many other fuel types. Still, today, diesel offers a unique combination of unmatched features: proven fuel efficiency, economical operation, power, reliability, durability, availability, easy access to fueling and service facilities.

We all benefit from a more efficient freight system. Fuel and powertrain choices are one part of that. The greatest opportunity for efficiency gains, fuel savings, lower greenhouse gas emissions and cleaner air – now – is to get more truckers into the newest generation of more fuel efficient and near-zero emissions clean diesel technology, as rapidly as possible.” added Schaeffer.

Asked about the future of diesel engines in trucking, Weston Labar, CEO of the Harbor Trucking Association says:

“We’re decades away from converting entire fleets from diesel for instance to electric because we just don’t know what it’s going to take to do that and we don’t have the wherewithal from an infrastructure standpoint to do it today. And so – until you have a low-cost competitive solution that would be able to rival what diesel brings to the table – you’re never going to be able to get fully away from diesel technology.

addvantage clean technologies offer both material fuel savings and emissions reductions which is absolutely what our industry needs.”

LaBar also confirmed that in the USA the typical fuel consumption of a class 8 heavy-duty truck is approximately 6.5mpg.

The economics are irresistible. Imagine a company with a fleet of 500 trucks, covering 100,000 miles per year per truck at an average of 6.5 MPG. After the cost of diesel, the LPG injected and the addvantage technology installed – that fleet with 500 trucks could achieve a net saving of $1,695,385 per year with no capital outlay.

Retrofit performance improvement for existing class 8 trucks, compelling economics, and better for the environment.

For more information or to arrange a demo, please contact Steve Clarke, our Chief Commercial Officer, on steve@addvantage.net

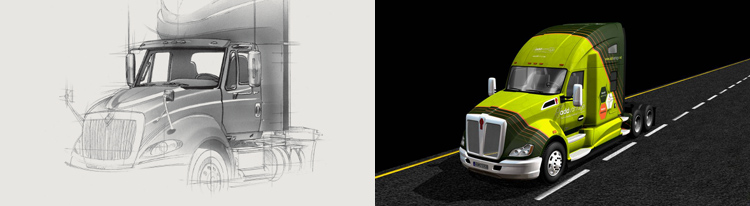

Having taken delivery of our new Kenworth T680 and had it wrapped nose to tail with the most fabulous head turning graphics we decided it was the perfect time to shoot a promotional video for our website and grab some super stills for other marketing material whilst the truck is in absolute pristine condition.

Having taken delivery of our new Kenworth T680 and had it wrapped nose to tail with the most fabulous head turning graphics we decided it was the perfect time to shoot a promotional video for our website and grab some super stills for other marketing material whilst the truck is in absolute pristine condition. The drone crew set up their “Inspire II”. It shoots high resolution video and still images. It requires a camera operator and a qualified pilot. Not surprising given that it can be flown remotely from 6 miles away and at speeds of up to 60 MPH. We didn’t push the envelope!

The drone crew set up their “Inspire II”. It shoots high resolution video and still images. It requires a camera operator and a qualified pilot. Not surprising given that it can be flown remotely from 6 miles away and at speeds of up to 60 MPH. We didn’t push the envelope!